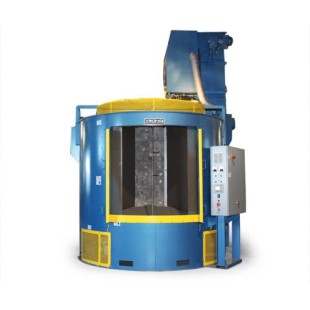

If you are looking for Shot Peening Equipment, to improve the performance and durability of your metal parts, you should consider shot peening with Viking Wheel Blast Systems.

Shot peening is a process that creates compressive residual stresses on the surface of the material, which prevent the propagation of cracks and increase the fatigue life of the component. Shot peening can also improve the wear resistance and corrosion resistance of parts by creating a smooth and uniform surface.

Viking’s equipment is manufactured and assembled completely in-house, ensuring optimum quality and performance. Their machines are also designed to be cost-effective and easy to use, with industry-leading warranties and service. Viking’s new VMAX center-fed, direct-drive blast wheel is the next evolution in the Viking line, offering more horsepower to the blade tip, smoother and quieter operation, and easier access to the outer liners and face plate.

With Viking Wheel Blast Systems, you can achieve outstanding finishes for your metal parts and enhance their mechanical properties and surface state by implementing our peening equipment to enhance the shot blast process.